WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Nov 03, 2010· This dualwheel vertical grinding machine is an alternative to two and fouraxis horizontal machines. Emag (Farmington Hills, Michigan) is applying the vertical grinding concept in a new way for long workpieces such as automotive camshafts. The concept uses dual, opposing grinding wheels that cut ...

(d)(2) Arbor size. Grinding wheels shall fit freely on the spindle and remain free under all grinding conditions. A controlled clearance between the wheel hole and the machine spindle (or wheel sleeves or adaptors) is essential to avoid excessive pressure from mounting and spindle expansion.

The versatility and wide application of the grinding processes have led to the development of many types of grinding machines. Your shop will probably have two, three, or more of the common types. As a machinist, you should be familiar with the many types of these machine .

The grinding wheel does not perform planetary motion and only reciprocates up and down. Grinding similar to the insertion type can be performed to machine the inner ring gear, the indexing plate and the cam. With the application of digital control technology, jig grinding machines have been able to grind various forming surfaces.

CNC ROTARY TABLE VERTICAL GRINDER VERTICAL UNIVERSALS GRINDERS: The most suitable for large diameter revolution jobs as motor casings, gears, bearings, turbines and other typical parts for sectors like power conversion, aerospace, marine. In general any kind of heavy part or light part in need of a heavy tooling that is difficult to be set up and ground in horizontal.

Vertical Mate 55 Vertical Grinding Machines and Vertical Grinding Centers by ... Home . Products . Machines . Grinding . Vertical Grinding . Vertical Mate Series . Vertical Mate 55 Vertical Mate 55. CNC Vertical MultiProcess Grinding Machine. Swing diameter ... Wheel spindle. Single spindle type : HSKA63; 2position turret with indexing ...

CNC Series(VIG2015E) PALMARY vertical grinding machine had honeycomb type machine structure assures the best possible rigidity and stability of vertical grinding machine. The machine bed is manufactured from highquality Meehanite cast iron, heat treated and stress relieved for outstanding stability and without deformaiton.

Swingarm vertical grinding machine DELTA Swingarm grinding machine Built in approximately 1988 Grinding range 255 x 125 mm Magnetic 255 x 125 mm Grinding amount grinding wheel, magnet approx. 240 mm Grinding amount grinding wheel clamping surface approx. 290 mm Grinding wheel diameter 178 mm Grinding wheel speed 2800 RPM.

Aug 09, 2017· 2. ID grinding TaiyoKoki Vertical Mate VM85 machine concept. ID grinding options are limitless on a vertical grinder. Typical horizontal universal grinders offer one or two OD wheels and one ID wheel. If the part to be ground requires significant stock removal, all ID grinding must be done with only one ID wheel.

#HTG24 OKAMOTO 4AXIS CNC STRAIGHT GEAR . SPLINE GRINDER. Wheelhead Vertical Travel, YAxis. to DP. External Gear Root Circle Dia, Minimum. NOTE: Machine Is Used For Grinding Spur Gears O...

Vertical Mate 55 Vertical grinding machines and vertical grinding centers from DMG MORI. Home . Products . Machines . Grinding . Vertical Grinding . Vertical Mate Series ... Wheel spindle. Single spindle type: HSKA63; 2position turret with indexing angle 0 and ゚ ...

CNC Vertical MultiProcess Grinding Machine. Compilation model which realizes further productivity improvement, by standardizing (Auto. Pallet Change) system in addition to the advantages of vertical grinding machine, such as high accuracy, process aggregation and workability improvement.

Machine use Grinding machine BUC 63 C Multi with programcontrolled automatic rotation of grinding wheel head along vertical axis and CNC control ... More information vertical disc grinding machine / for metal sheets / CNC / 2axis BUC 85 C Multi

historic grinding machine with two vertical wheels. Grinding machine,, New, Surface Grinding Machine, from Majevica on basic elements of the machine such as the body, tables, column and the other cast parts have been annealed two times thus eliminating themm/min. 150. 1 revolution on vertical hand wheel. Chat Online +

VERTICAL TRANSLATION SCREW supported by opposite and adjustable ball bearings, with apt motion for maintaining, in this model of grinding machine with fixed table, the wheel work field free from hindrances and for avoiding dust depositions. Metal BELLOWS for a better protection of the vertical translation screw of the grinding machine.

Surface grinding is used to produce a smooth finish on flat surfaces. It is a widely used abrasive machining process in which a spinning wheel covered in rough particles (grinding wheel) cuts chips of metallic or nonmetallic substance from a workpiece, making a face of it flat or smooth.

Lower your total perpart grinding costs with our selection of toolroom grinding wheels that deliver precision part quality finishes in many applications. Available to fit many sizes and specification of machines with speed, quality and finish in mind. Review our selection include ID and bearing wheels, cylinder wheels, and other shapes.

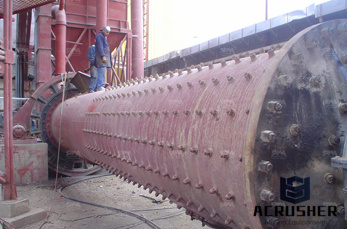

What is Vertical Grinding? CNC Cylindrical MultiProcess Vertical Grinding is a grinding method in which the workpiece is held upright in a rotating chuck and multiple precision grinding processes such us OD grinding, ID grinding and face grinding can be done in a single chucking.

Surface Grinding Machines. Surface grinding machines use horizontal spindles and reciprocating tables. In the surface grinding process, the grinding wheel revolves on a spindle; and the work piece, mounted on either a reciprocating or a rotary table, is brought into contact with the grinding a surface grinding machine is the most preferred machines for finishing flat surfaces ...

Single disk grinding machines use a rotary table to mount the parts while usually a vertical spindle grinding wheel is grinding the parts. On the same machine and using the same rotary table, also two spindles can be mounted, for coarse grinding and for fine grinding.

There are two types of cylindrical grinders, one that has a center and the other is center less. A cylindrical grinding machine may have multiple grinding wheels. Here the work piece is rotated and fed through the wheels to form a cylinder. It is widely utilized to manufacture accurate objects like tubes, rods, bushings, bearings, and other parts.

Oct 28, 2004· Vertical grinding is certainly a case in point. Vertical grinding, as the name implies, fixtures the workpiece on a rotary chuck in the base of the machine, similar to the workpiece orientation on a vertical lathe. The grinding spindle travels up and down and side to .

History of the grinding machine: a historical study in tools and precision production Volume 2 of Technology monographs. Historical series Issue 2 of Technology monographs (Massachusetts Institute of Technology).: Historical series Issue 2 of Massachusetts Institute of Technology. Technology monographs: his torical series: Author: Robert S ...

Our company is widely appreciated by offering Vertical Surface Grinding Machine to the clients. Vertical Surface Grinding Machine is made up by the experts using high quality material and using of advanced technology. This product is provided in various specifications, designs and sizes as the requirement of the clients.