WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

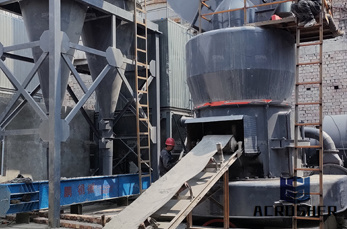

The vertical mill is recognized worldwide for its energy saving, environmental protection and high efficiency. The grinding table is an important part. The grinding table is mainly composed of disc body, lining plate, pressing block, retaining ring, scraping plate, wind ring and air deflector.

5 The core components of the roller mill include: xthe wearprotected grinding table with double groove grinding track xtwo roller pair units which adapt independently to the bed of material by vertical movement and by pivoting around their

Grinding table is one of key parts of vertical roller mill. It includes drag rings, lining plate and base. The optimization and improvement are made basing on traditional grinding table casting technology, that the most advanced sodium silicatebonded sand molding technology, to overcome deficiencies in structure and make the grinding base bear force equivalently.

This milling table for a drill press is short but sturdy and is made of a full cast iron base to reduce vibrations. Browse more vertical mill drills today.

The anatomy of HLMX vertical mill. Grinding roller: Main component used for crushing and grinding materials. Together with the liner plate on the grinding plate, it can provide an effective grinding area. ... Without raw material on the grinding table, the mill can run, which erases the difficulty in starting. ...

9" x 49" Used (Demo Machinery) Baileigh Variable Speed Vertical Milling Machine (Inverter Head) With 2 Axis Dro and X/Y/Z Power Feeds, Mdl. VM9493, 2 Axis DRO, Inverter Head, Pneumatic Power Draw Bar, Power Feed on X, Y Z Axis, NST40 Spindle Taper, Table Knee Locks, Reversing Quill, Turcite B® Coated Ways Guides, Meehanite® Castings, Way Covers, Chip Tray, Adjustable Work Light ...

Jul 11, 2019· tables have the features of high hardness, good anticracking. carry out grinding table dressing and finishing machining by arc air .

The DDTM5922 grinding table from Baileigh Industrial can help. This easy to use down draft table takes all the little partials that float around the shop and pull them straight down into a contained unit and also help to clean the air.

Mar 14, 2018· Grinding table for vertical mill Introduction The grinding table is mainly composed of table body, lining plate, press block, retaining ring, scraper plate, air ring, and wind deflector, etc.. The main function of the grinding table is to support the material bed and transfer the force from the grinding roller to the reducer at the lower part.

Jun 14, 2019· Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mill''s main components, how it works and some of its design features. For this video, we assume ...

JET Vertical Milling Machines are manufactured for precision, reliability and durability. Table sizes ranging from 8" x 36" to 12" x 54" and drivetrains of step pulley, variable speed, and electronic variable speed allow for easy mill selection.

This vertical roller mill uses a hydropneumatic system to press its grinding rollers against the material bed on the rotating grinding table. Complete size range to fit your grinding needs The OK™ Mill is offered in a complete size range, including 3, 4 and 6roller mills, and the largest vertical roller mill size available with installed ...

Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal. The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a separate piece of equipment for crushing.

Vertical Roller Mill Summary Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. Ball mill vs. vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance Improvement

As the only machine tool OEM provider offering turning, milling, grinding, workholding and custom manufacturing solutions, Hardinge is ideally positioned to provide you with an innovative, costeffective custom solutions that meets your needs. Learn More

Table top hammer mill. ... Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a grinding process. ... Arrastra, simple mill for grinding and pulverizing (typically) gold or silver ore.

The above photo depicts how the milling machine table was ground. The table being ground in this view is from a Bridgeport vertical mill. Any mill or drill marks in the table top are welded with nickel rod and the top of the table is lightly milled and ground flat. The sides are ground next.

The grinding Table of Vertical Roller Mill is one of the key parts of vertical roller mill. It includes drag rings, segments (lining plate) and bases. The optimization and improvement are made by us on the traditional grinding table casting technology, that the most advanced sodi

vertical roller mill Application process Raw material process Background In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the mill as drying, transporting and separating purpose.

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology ... The grinding process in ball mills and vertical roller mills differ fundamentally. In a ball ... rollers and the table of the vertical roller mill, able to sustain such a pressure without ...

Every Fabrication shop has the need for a welding and grinding station, but this is one of the messiest places in the shop. The DDTM8024 metal working downdraft table from Baileigh industrial can help with that. This 80" long grinding table features a 3mm thick work table made out of stainless steel and can hold up to 660lbs.

ECUTEC''s Atlas Vertical Roller Mills have been developed for more efficient fine grinding of soft to mediumhard materials.. The Atlas is a roller airswept mill designed for continuous operation with minimum maintenance. The fundamental difference between the Atlas and other tableroller mills is the bearing arrangement for the grinding table which is incorporated into the base of the mill.

Overview The grinding table is one of the key parts of vertical roller includes drag rings, segments (lining plate) and bases. The optimization and improvement are made by us on the traditional grinding table casting technology, that the most advanced sodium silicatebonded sand molding technology, to overcome the deficiencies in structure and enable the grinding base to bear force ...

Large, Precision, Complex Machining Capabilities in our Machine Shop. Class Machine Description Image HBM Parpas Horizontal Mill 60 ton rotary table, 355″ longitudinal, 142″ vertical, cross ram, with five axis head, universal head, CNC facing head. Very large complex machining capability. VTL Large CNC vertical boring mill with live tooling.